In der industriellen AbwasserbehandlungPolyaluminiumchloridPAC wird häufig als hochwirksames Koagulationsmittel in Fällungs- und Klärprozessen eingesetzt. Bei der Verwendung von polymerem Aluminiumchlorid kann es jedoch aufgrund überschüssiger wasserunlöslicher Bestandteile zu Rohrverstopfungen kommen. Diese Arbeit befasst sich detailliert mit diesem Problem und schlägt eine entsprechende Lösung vor.

Bei der industriellen Abwasserbehandlung kann polymerisiertes Aluminiumchlorid gelegentlich zu Rohrverstopfungen führen. Dies kann einerseits auf unsachgemäße Bedienung zurückzuführen sein, andererseits aber auch auf die Eigenschaften des polymerisierten Aluminiumchlorids selbst, beispielsweise einen hohen Anteil an wasserunlöslichen Bestandteilen. Um einen reibungslosen Ablauf der Abwasserbehandlung zu gewährleisten, müssen geeignete Maßnahmen ergriffen werden, um die verschiedenen Ursachen des Problems zu beheben.

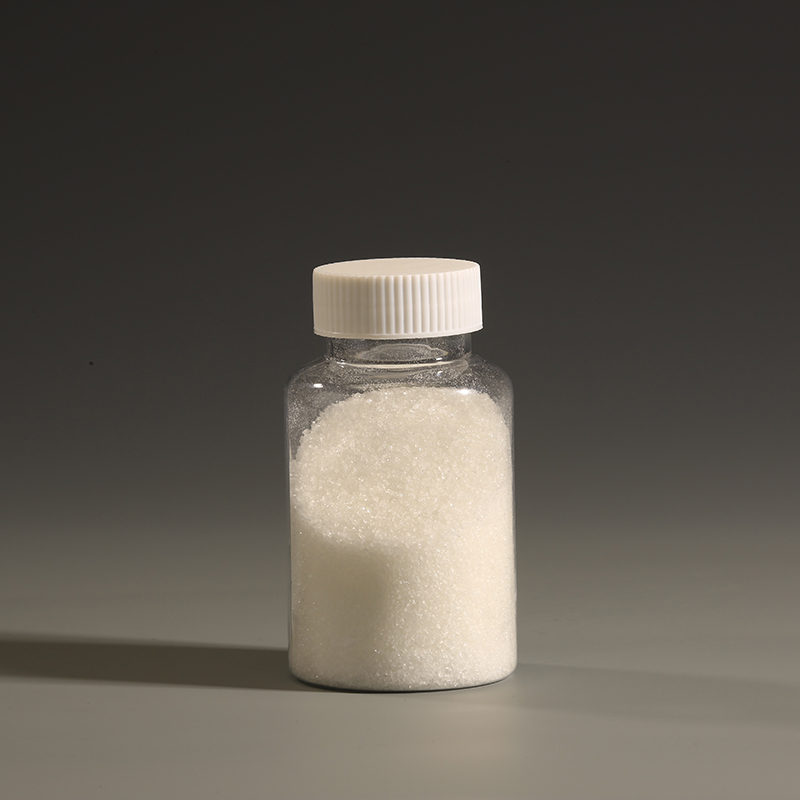

Auswahl von hochwertigem Polyaluminiumchlorid

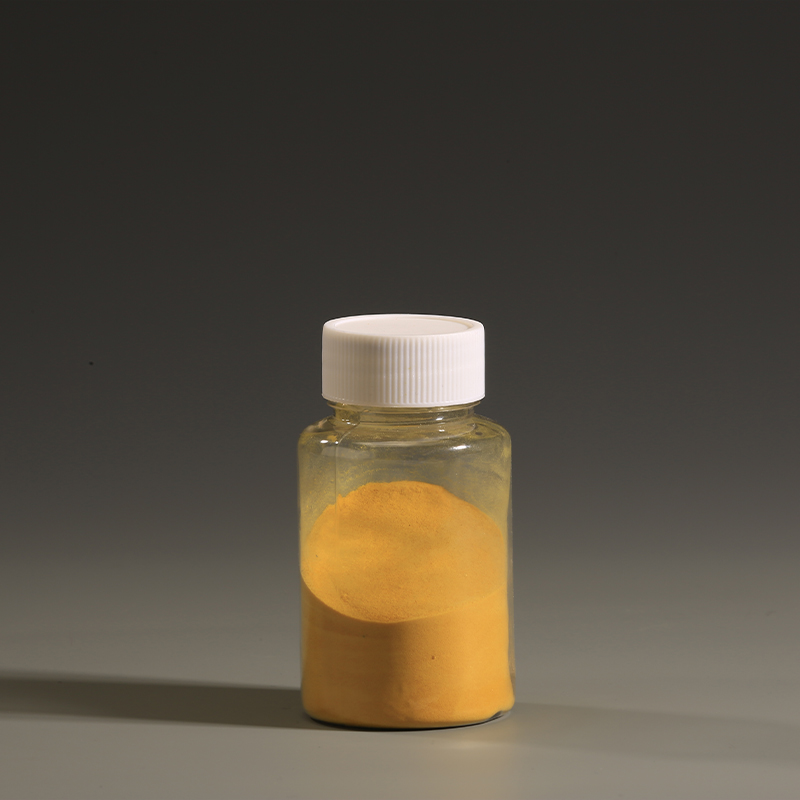

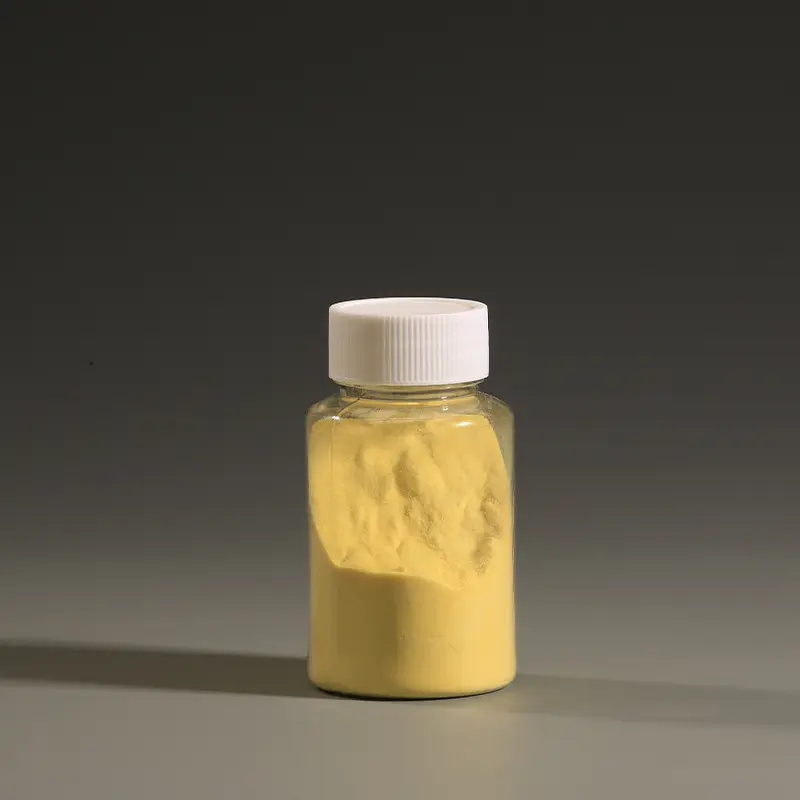

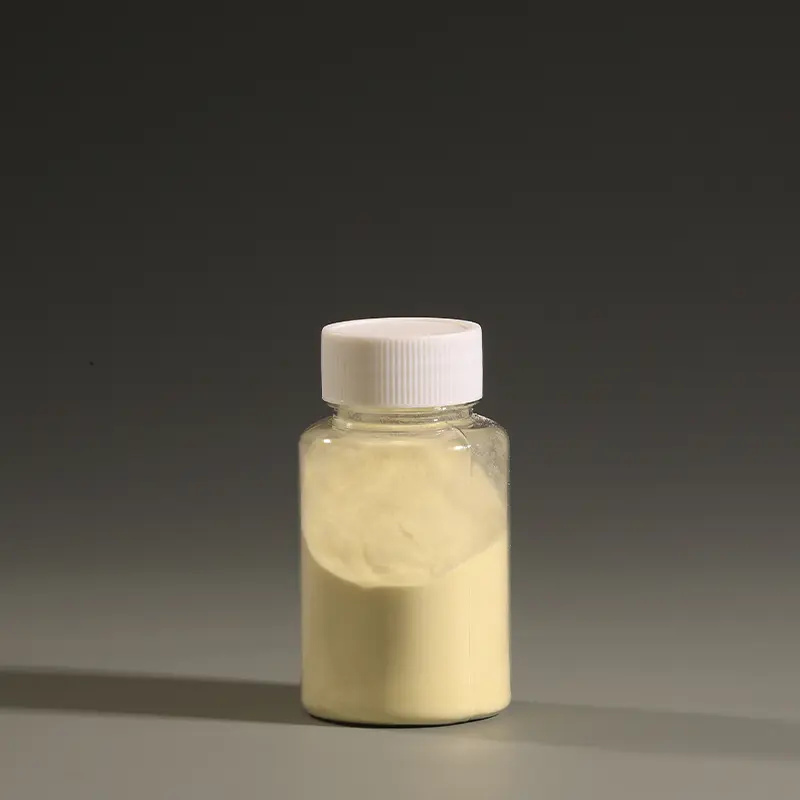

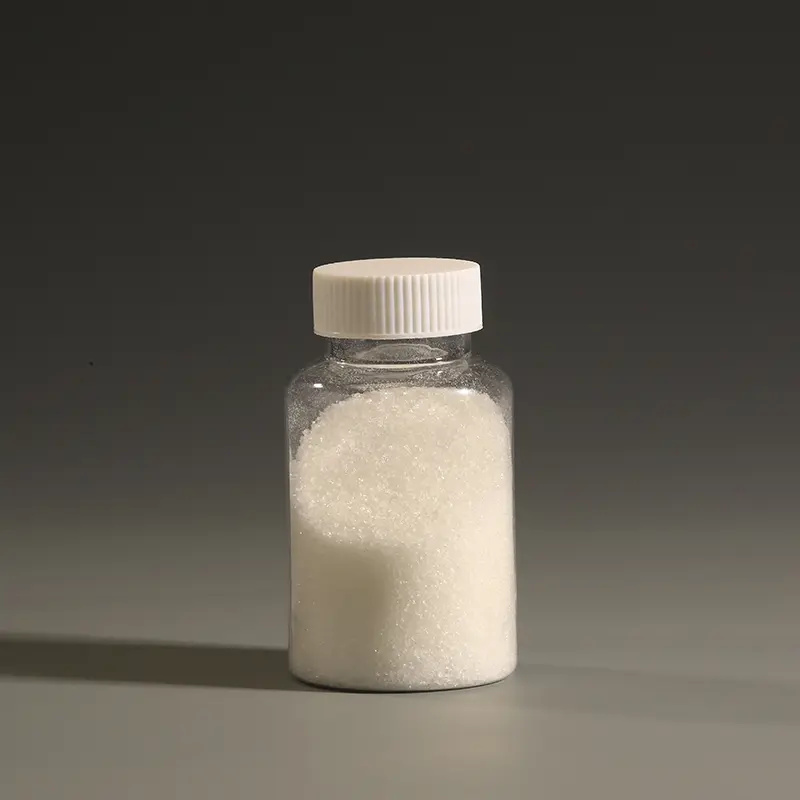

Hochwertiges PACEs sollte sich durch einen geringen Gehalt an wasserunlöslichen Bestandteilen und wenige Verunreinigungen auszeichnen. Ein Überschuss an wasserunlöslichen Bestandteilen ist die Hauptursache für Rohrverstopfungen. Werden die Rohstoffe im Produktionsprozess nicht sorgfältig ausgewählt und die wasserunlöslichen Bestandteile nicht ausreichend behandelt, sodass der Gehalt an wasserunlöslichen Bestandteilen hoch ist, kann es bei Anwendern von polymerisiertem Aluminiumchlorid (PAC) nach einer gewissen Nutzungsdauer zu Rohrverstopfungen kommen. Dies beeinträchtigt nicht nur die Behandlungswirkung, sondern kann auch erhebliche wirtschaftliche Verluste verursachen. Daher sollten Sie beim Kauf von polymerisiertem Aluminiumchlorid nicht nur auf den Preis achten, sondern auch auf zuverlässige Qualitätsprodukte.

Wenden Sie die korrekte Anwendungsmethode an.

Vor der Verwendung von polymerisiertem Aluminiumchlorid muss der Feststoff im Verhältnis 1:10 vollständig gelöst werden. Bei unzureichender Auflösung kann die Lösung mit ungelösten Feststoffen die Rohre leicht verstopfen. Um eine optimale Auflösung zu gewährleisten, ist es wichtig, die Löseleistung der verwendeten Geräte zu kennen und die passenden Mischvorrichtungen auszuwählen. Sollten sich Feststoffpartikel am Boden absetzen, sind umgehend Maßnahmen zu ergreifen, um Verstopfungen zu vermeiden.

Lösung: Verstopfte Rohre beseitigen

Um das häufige Auftreten von Rohrverstopfungen zu vermeiden, sollten Sie folgende Punkte beachten:

Installieren Sie Filter vor der Pumpe und überprüfen und wechseln Sie diese regelmäßig; vergrößern Sie den Rohrdurchmesser, um die Verstopfungsgefahr zu verringern; verbessern Sie die Spülvorrichtung der Rohrleitung, damit diese bei Verstopfungen gespült werden kann; halten Sie eine geeignete Temperatur aufrecht, um eine Kristallisation bei niedrigen Temperaturen zu vermeiden; verwenden Sie federbelastete Tellerventile, um sicherzustellen, dass die Lösung mit ausreichendem Druck in das Wasser eingespritzt wird, um das Verstopfungsrisiko zu verringern.

Darüber hinaus gibt es einige weitere Vorschläge, um Verstopfungen in Rohrleitungen vorzubeugen: Versuchen Sie nicht, billige und minderwertige Produkte auszuwählen; achten Sie auf das Verdünnungsverhältnis des Produkts, um eine vollständige Auflösung zu gewährleisten; überprüfen und reinigen Sie die Rohrleitungsausrüstung regelmäßig, um die Bildung von Kristallisation und Ausfällung zu verhindern.

Sollten Sie Bedarf an hochwertigen Polyaluminiumchlorid-Produkten haben, besuchen Sie bitte unsere offizielle Website. ProfessionellChemikalien zur WasseraufbereitungUnser Team steht Ihnen gerne zur Verfügung, um Ihnen optimale Lösungen und hochwertige Produkte anzubieten. Unsere professionellen Dienstleistungen unterstützen Sie bei der Bewältigung vielfältiger Herausforderungen in der industriellen Abwasserbehandlung und tragen zur Steigerung der Behandlungseffizienz und Wirtschaftlichkeit bei.

Veröffentlichungsdatum: 21. Oktober 2024